In the scramble for an adequate supply of PPEs amid the COVID-19 pandemic, Lawrence University is getting a needed boost from its own Makerspace.

Using 3D printing technology, Reference and Learning Technologies Librarian Angela Vanden Elzen and student intern Kelvin Maestre ’21 have led efforts this summer to 3D print 200 plastic face shields and 150 ear savers in the Makerspace lab inside the Mudd Library.

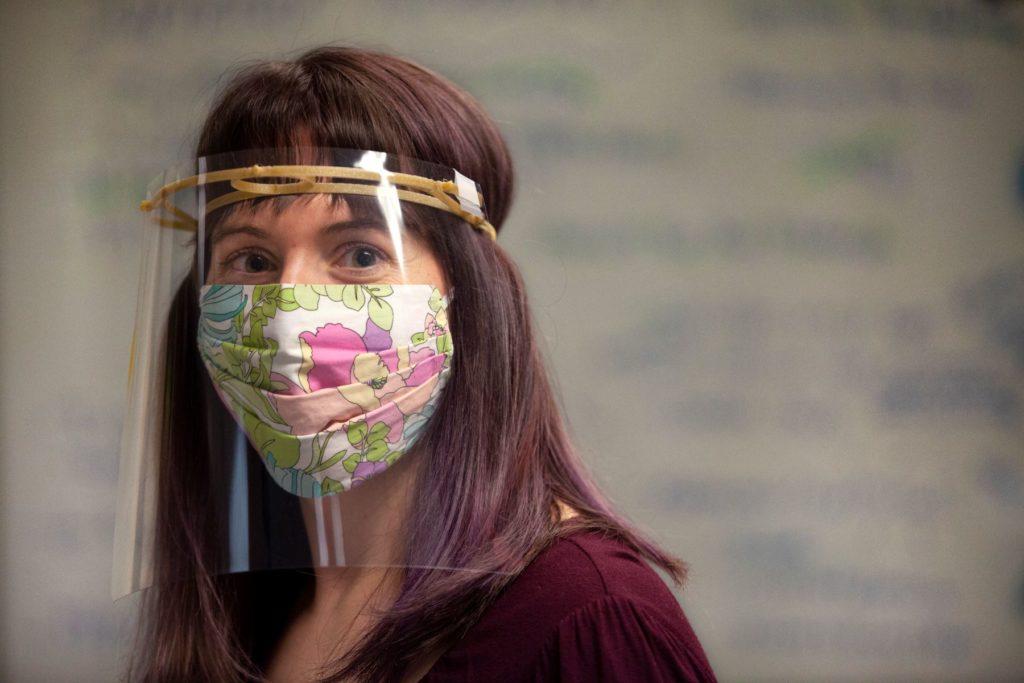

The Makerspace’s personal protective equipment (PPEs), as well as cloth face masks made by students through the Conservatory’s costume shop, are now being distributed on campus through Wellness Services. The face shields provide another layer of protection beyond masks and the ear savers offer a more comfortable way of securely wearing a mask.

“This work began on a more exploratory level at the start of the summer,” Vanden Elzen said of the Makerspace efforts. “We found 3D printable files for both the ear savers and the face shield visors on the NIH (National Institutes of Health) 3D print exchange. They’ve created a special COVID-19 response collection of objects that have either been tested for clinical use or community use. It was important for us to find designs that were created by scientists and professionals in the medical field.”

Kelvin Maestre ’21 joined Angela Vanden Elzen in the Makerspace this summer in the building of face shields and ear savers, adding to needed PPE inventory on the Lawrence University campus.

Vanden Elzen and Maestre went to work prepping the Makerspace technology to make large batches on the 3D printers. That proved to be pretty easy for the ear savers, where they could print five at a time using two printers. Additional parts or modifications weren’t needed.

The face shields production, meanwhile, was a different story. Initially, only two would fit on a printer at a time, so Maestre, an anthropology major from Revere, Massachusetts, explored ways to modify the process. When he was done, they were able to print 16 at a time, using all three of the 3D printers.

Read more about Makerspace possibilities here.

“After doing some research, I learned how to print the shields in stacks of 16,” Maestre said. “All you need is the right amount of gap between each shield that would allow you to separate them. In our case, the shield was 5 millimeters tall and we used a .2 millimeter layer height to print, so we used a gap of .21 millimeter between each shield to make them separable.”

After Maestre’s ingenuity got production rolling, it was time to recruit some help for the visor construction, which came enthusiastically from other workers in the library.

“It takes a bit of time to carefully separate the visors and sand any rough edges or bumps from the printing process to make them comfortable to wear,” Vanden Elzen said. “The shields then need the actual shield part. We ordered plastic folder covers that each need to be 3-hole punched. The finishing piece is two looped-together rubber bands to hold the visor on the wearer’s head.”

In all, 200 plastic face shields and 150 ear savers were created in Makerspace.

When she asked other library staff members if they might be willing to help if they had any extra time, the response was immediate. And enthusiastic.

Vanden Elzen and Maestre then set up four stations in front of the Makerspace to allow for social distancing. They filled the tables with the tools and supplies needed to make the visors, along with a container of sanitizing wipes.

“I absolutely love what this project has turned into,” Vanden Elzen said. “It started with Erin Buenzli (director of wellness and recreation) reaching out to Kelvin and me in the Makerspace to see if we could help provide PPEs, and then it turned into this awesome community effort.”

The Makerspace-produced PPEs will benefit the Lawrence community without drawing down the supply elsewhere in the Fox Valley. Wellness Services has the growing inventory of ear savers, masks, and face shields. Department supervisors, employees, and students on campus can request them by using the mask-request web form or by e-mailing Buenzli.

“I’m excited to be using our resources so that we don’t use PPE supplies that are needed elsewhere,” Buenzli said. “The PPEs will help protect our essential workers, and the ear savers will create a better fitting and more comfortable mask.”

Vanden Elzen said the Makerspace is also ready to lend a hand if anyone on campus is in need of custom-built PPEs.

“If it’s something we can 3D print, sew, or laser cut, we’re happy to help,” she said.

The PPE project, Vanden Elzen said, is further evidence of what the Makerspace can become as technologies advance and more students embrace the possibilities.

“It seems like we’re learning new things all the time about what these tools can do,” she said.

“Making 200 shields has been a long process, but I already feel good knowing that our work will be directly helping other students stay safe,” Maestre said.